Presentation of the DYNAMIXEL YM080-230-A051-RH Servo Motor

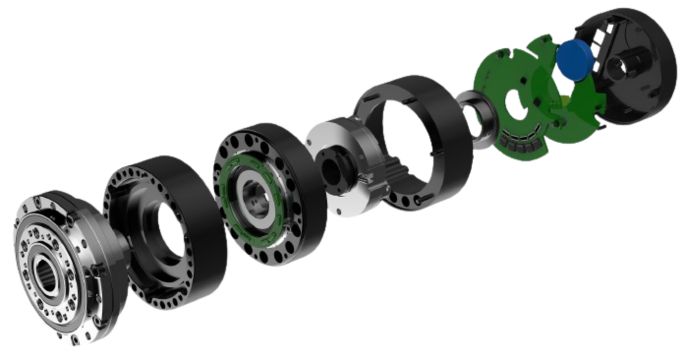

The YM080-230-A051-RH servo motor features a high-performance frameless motor with a hollow shaft. It uses an integrated cycloidal reducer, offering a compact and powerful solution for robotic systems requiring precise control of position, speed, and torque.

Important note: The DYNAMIXEL DRIVE (DYD) cannot be replaced after the product has been purchased.

Main Features

- High-performance frameless motor with hollow shaft

- Torque control based on current detection

- PID control to improve reliability and precision of position and speed

- Integrated absolute magnetic encoder with replaceable battery allowing for multi-turn position data retention even after a complete power outage (with backup battery)

- Metal housing for high durability

- Modular configuration facilitating the creation of applications with different degrees of freedom

Package Components

| Product |

Quantity |

Remark |

| YM080-230-A051-RH |

1 |

DYNAMIXEL-Y (option R) |

| Robot Cable-2P-X4P 600mm (Convertible) |

1 |

RS485 2P-4P Cable (MOLEX-JST) |

| Robot Cable-2P 600mm |

1 |

RS485 2P Cable (MOLEX-MOLEX) |

| Eye Terminal |

4 |

For power connection |

| Plug Connector |

2 |

For power connection |

| WB M3X20 Mounting Screws |

14 |

For assembly of the shaft frame |

| WB M4x10 Mounting Screws |

10 |

For assembly of the frame |

How to connect the multi-turn backup battery

- Disconnect the power from the DYNAMIXEL-Y and loosen the locking screw on the battery cover.

- Open the battery cover.

- Connect the battery cable.

- Rescrew the battery cover.

- Tighten and secure the locking screw on the battery cover.

- Run the DYNAMIXEL Wizard 2.0 program and follow the battery replacement procedure.

- Refer to the electronic manual for further details.

Precautions

- Warning!

- Due to the material properties, rust may occur depending on the operating environment.

- Repairs related to rust may incur charges. To avoid this, please reduce humidity and improve ventilation.

- Salt removal and anti-corrosion treatment should be carried out regularly.

- Ensure that the operating voltage is 24V, which is different from other DYNAMIXEL series.

- Refer to the drawings provided online when associating with other power transmission products.

- This product is designed as an integral unit: the cycloidal reducer and motor cannot be separated for individual use.

- Please be cautious of overheating during prolonged high-speed use.

- Use a frame matching the screw length, taking into account the depth of the tabs indicated in the drawing.

- After purchase, make sure to connect the multi-turn backup battery before use.

Applications

This product is designed for applications requiring precision in positioning and speed, particularly in modular robotic systems or custom configurations.

DYNAMIXEL YM080-230-A051-RH Servo Motor Technical Specifications

- MCU: ARM Cortex-M4 (168 MHz, 32 bits)

- Voltage: 24.0 V

- No-load speed: 62 RPM

- Torque: 15.8 N·m

- Speed: 39 RPM

- Current: 12.6 A

- Resolution [deg/pulse]: 0.0000134636

- Steps [pulse/rev]: 26,738,688

- Angle: 360°

- Position sensor: Absolute contactless encoder (19 bits, 360°), Multi-turn (18 bits, 262,144 turns), backup battery

- Operating temperature: -5°C - 55°C

- Motor: BLDC frameless

- Baud rate: Min: 9,600 bps / Max: 10,500,000 bps

- Control algorithm: PID

- Gear material: Metal

- Housing material: Metal (plastic bottom)

- Dimensions: D80 x 100.1 mm

- Weight: 1,550 g

- Gear ratio: 51:1

- Command signal: Digital packet

- Protocol: Asynchronous semi-duplex serial communication (8 bits, 1 stop bit, no parity)

- Link (physical): RS-485 multipoint bus

- Identifier: 0 ~ 252

- Feedback: Position, speed, current, temperature, voltage, etc.

- Protocol version: Modbus 2.0

- Output power: 230 W

- Standby current: 40 mA

DYNAMIXEL YM080-230-A051-RH Resources