Get a quote in only 3 steps!

1. Add the items you are interested in to your cart

2.Go to your cart

3.Click on GENERATE A QUOTE

Tous vos devis sont accessibles à partir de votre compte client.

Including €0.05 for ecotax

The Dynamixel XC430-W240-T servo motor generates one of the most powerful torque in its class for a lower energy consumption.

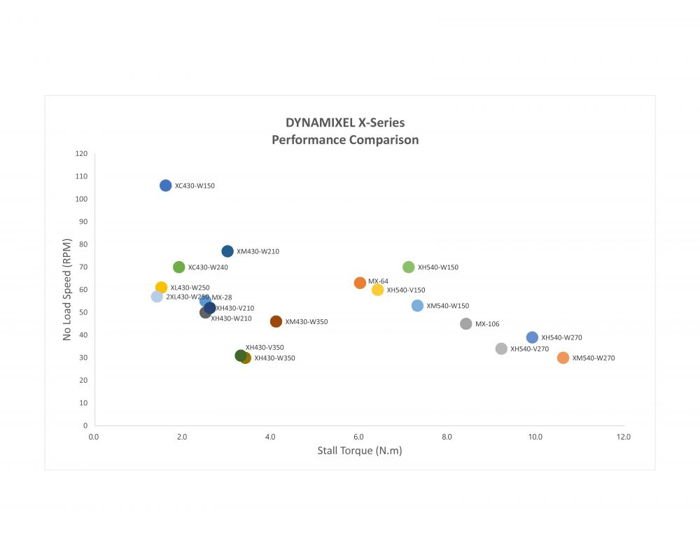

The XC430-W240-T model is a servo featuring a TTL interface and a 245.2:1 reduction ratio and offering a no-load speed of 70 RPM. It is a servomotor that is positioned above the XL 430 servo with its high torque and low energy consumption. Its characteristics allow it to equip more powerful robots or mobile vehicles designed for exploring the roughest terrain.

Our Dynamixel XC430-W240-T servo comes with a compatible idler delivered ready for installation, complete with its set of screws. You also get an X3P 18 cm robotics cable to connect the servo to your microcontroller.

Dynamixel, by Robotis, is a complete range of intelligent, autonomous and ultra-adaptable servo motors. Dynamixel servos offer RS232 and TTL connections and can be adapted for use in the most complex robotics creations. They can combine different levels of power and speed, depending on your project’s needs. A high reduction ratio will serve well for an all-terrain vehicle or a robot designed to carry heavy loads, while a rapid servo will be a better choice for your more agile creations.

The Robotis Dynamixel servo motors can be programmed from A to Z using an Arduino or Raspberry Pi microcontroller. You can connect it with an X3P robot cable, and even daisy-chain several servos using the same method.

Dynamixel servos have an innovative shell design that reduces heat dissipation and allows numerous assembly configurations. The forces exerted on connection cables are also limited.

Find the right info about the Dynamixel XC430-W240-T servo with this list of links compiled just for you:

Check that your Dynamixel servomotor is correctly configured. Do not hesitate to re-flash it with the ROBOTIS Software Roboplus. After re-flash remember to re-configure it. If the issue is not solved, contact us for an advanced support.

The motor is probably not well mounted. Check that you correctly mounted the horns by respecting the mark.

There is probably a mechanical issue with the Dynamixel servomotor. You can directly contact us to get more advance support.

Check your power supply and the system cabling (try with a different servomotor). You can also reset the servo. If nothing works, the best solution is to go through the Dynamixel servomotor checklist!

The 1.0 protocol is dedicated to the Dynamixel AX and MX series. Protocol 2.0 is for the X and Dynamixel Pro series. Protocol 2.0 control tables include PID controls which allow for more precise adjustment of the servo motor movements. Protocol 2.0 can be updated on MX series servo motors. You can refer to the protocol 1.0 and protocol 2.0 pages for more informations.