Get a quote in only 3 steps!

1. Add the items you are interested in to your cart

2.Go to your cart

3.Click on GENERATE A QUOTE

Tous vos devis sont accessibles à partir de votre compte client.

Including €0.10 for ecotax

The Dynamixel XH540-W270-R servo motor can generate a powerful torque and offers numerous control options to the most hard-to-please robotics engineers and fans of all-terrain vehicles.

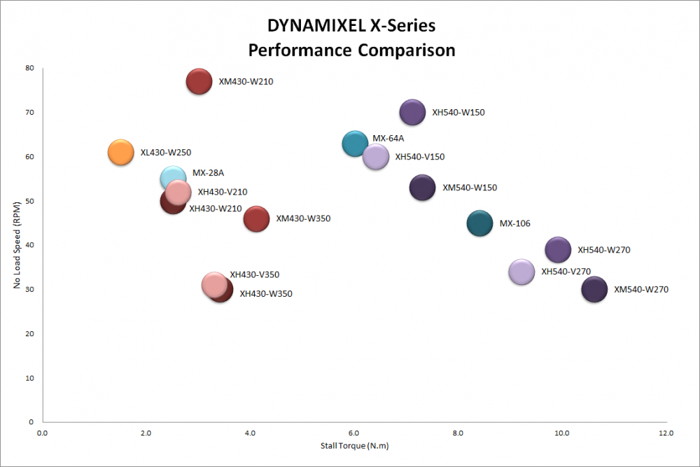

This Dynamixel servo offers a reduction ratio of 275:1 which makes it a great fit for robotic devices exploring difficult terrain. It is slower than the XH540-W150-R model, but it generates a more powerful torque.

As with all the XH series servos, you’ll benefit from an all-in-one device: you’ll only need to connect it to your controller or a USB2Dynamixel module and a power supply to get immediately started. Fully programmable, it offers extended torque, position, velocity or PWM control with a total of 6 operating modes. You can use the provided JST-Molex cable to connect it to its controller, as the Dynamixel XH540-W270-R servo motor has a gold-plated JST-compatible connector, which is much more reliable than the Molex connector used in the previous series.

The Dynamixel XH540-W270-R servo motor benefits from a high-quality design: its precious metal and engineering plastic casing delivers satisfactory heat dissipation.

At the back of the case, you can position the connection cable in 3 different arrangements. And with the suitable frames, you can mount your Dynamixel servo in many configurations, which is particularly useful if you’re planning to build a complex robot.

Finally, the Dynamixel XH540-W270-R servos can be linked together in a daisy chain.

We’ve compiled all the resources you’ll need to make the most of your Dynamixel XH540-W270-R servo motor.

Check that your Dynamixel servomotor is correctly configured. Do not hesitate to re-flash it with the ROBOTIS Software Roboplus. After re-flash remember to re-configure it. If the issue is not solved, contact us for an advanced support.

The motor is probably not well mounted. Check that you correctly mounted the horns by respecting the mark.

There is probably a mechanical issue with the Dynamixel servomotor. You can directly contact us to get more advance support.

Check your power supply and the system cabling (try with a different servomotor). You can also reset the servo. If nothing works, the best solution is to go through the Dynamixel servomotor checklist!

The 1.0 protocol is dedicated to the Dynamixel AX and MX series. Protocol 2.0 is for the X and Dynamixel Pro series. Protocol 2.0 control tables include PID controls which allow for more precise adjustment of the servo motor movements. Protocol 2.0 can be updated on MX series servo motors. You can refer to the protocol 1.0 and protocol 2.0 pages for more informations.