Get a quote in only 3 steps!

1. Add the items you are interested in to your cart

2.Go to your cart

3.Click on GENERATE A QUOTE

Tous vos devis sont accessibles à partir de votre compte client.

Including €0.01 for ecotax

To obtain the most innovative articulated robotics platforms, you need a talented designer (check!) and high-performance servos such as the XH430-W350-R, the latest creation of the Robotis team.

The new XH-series Dynamixel servos by Robotis (the H standing for High-performance) opens up a whole new range of possibilities for controlling your robot’s movement, trajectory or speed. These servos offer no fewer than 6 operating modes:

Robotis has also put together an exclusive advanced control table for controlling and editing a large array of data. This control table is available on Windows, Mac, or Linux.

As usual, you can use your PC (Windows, Mac, or Linux) with the USB2Dynamixel or a suitable microcontroller to control your Dynamixel servo (see below th elist of the required components):

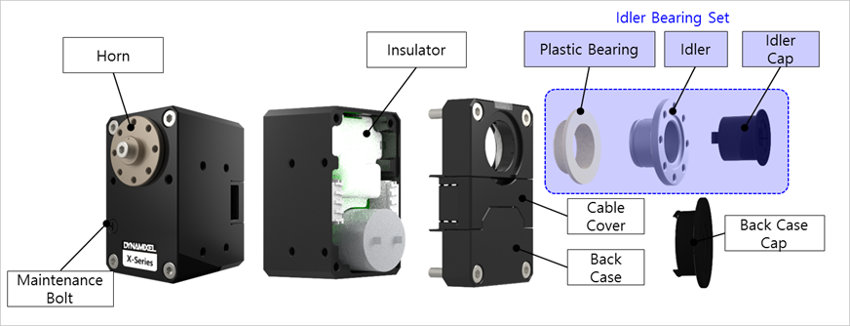

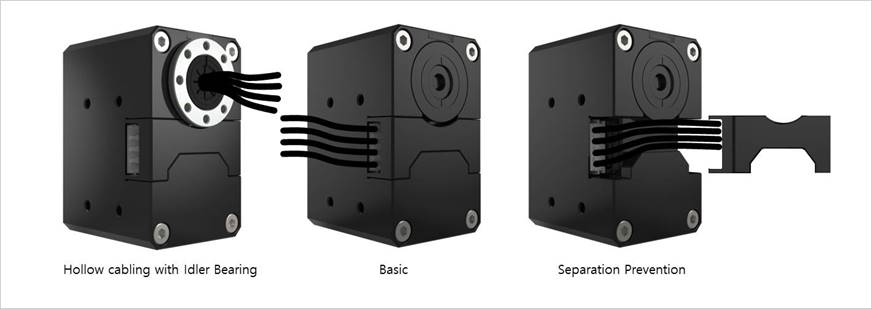

The Dynamixel XH servo has a robust, yet compact design, and is more energy-efficient. Also, it increases your mounting possibilities as the connecting cables can be set up in three different positions (keeping them out of the way when the servo is on). What’s more, you can mount your servo on its articulated structure in many ways.

You are probably eager to test your Dynamixel XH servo, but do take a few minutes to check these useful links!

Check that your Dynamixel servomotor is correctly configured. Do not hesitate to re-flash it with the ROBOTIS Software Roboplus. After re-flash remember to re-configure it. If the issue is not solved, contact us for an advanced support.

The motor is probably not well mounted. Check that you correctly mounted the horns by respecting the mark.

There is probably a mechanical issue with the Dynamixel servomotor. You can directly contact us to get more advance support.

Check your power supply and the system cabling (try with a different servomotor). You can also reset the servo. If nothing works, the best solution is to go through the Dynamixel servomotor checklist!

The 1.0 protocol is dedicated to the Dynamixel AX and MX series. Protocol 2.0 is for the X and Dynamixel Pro series. Protocol 2.0 control tables include PID controls which allow for more precise adjustment of the servo motor movements. Protocol 2.0 can be updated on MX series servo motors. You can refer to the protocol 1.0 and protocol 2.0 pages for more informations.