-

Visit our shop

Visit our shop

-

English

In 2019, Amazon chose to introduce some 4,000 robots among its employees at the distribution centre in Brétigny-sur-Orge.

Why? To reduce delivery times, increase productivity and relieve employees.

One example is the mobile Robo-Stow robot, which has an automated arm designed to lift and move heavy goods at Amazon’s warehouses. It can stack and unpack pallets.

By automating warehouse tasks, Amazon hopes to dispatch in 12 hours instead of 24, and ultimately deliver products to customers on the very day of ordering. The e-commerce giant is also planning to create fully automated warehouses.

They also use the Bunker Pro mobile robot by AgileX, ideal for carrying heavy loads and reducing the burden on employees:

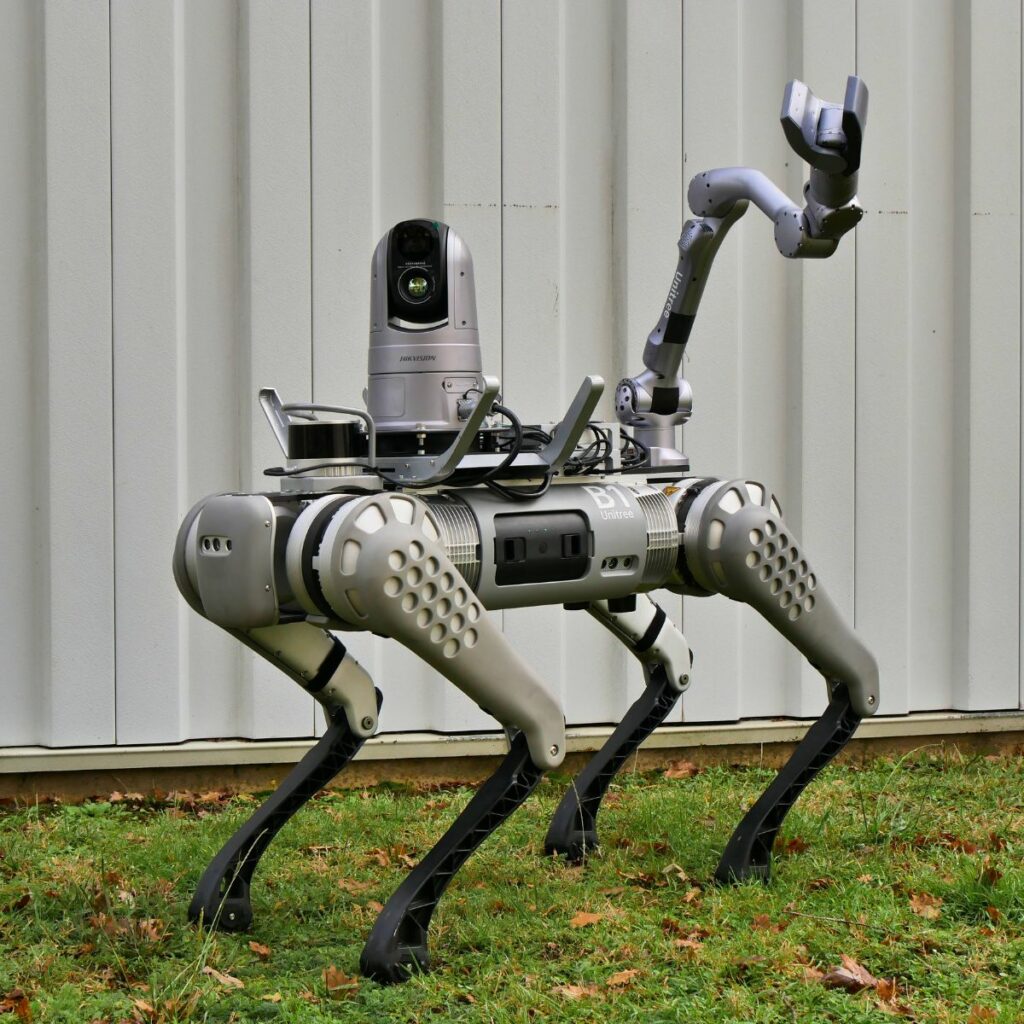

The future is looking particularly rosy for mobile robots equipped with robot arms. Advances in robotics technology, artificial intelligence and sensors are making them increasingly powerful and versatile.

Equipped with a robotics design office (GRLAB), Génération Robots can design solutions based on your specifications.